Project Title

Project Title

Indirect Evaporative Coolers on Packaged Rooftop Units

Project Number ET13SDG8021 Organization SDG&E End-use HVAC Sector Commercial, Public Project Year(s) 2013 - 2016Project Summary

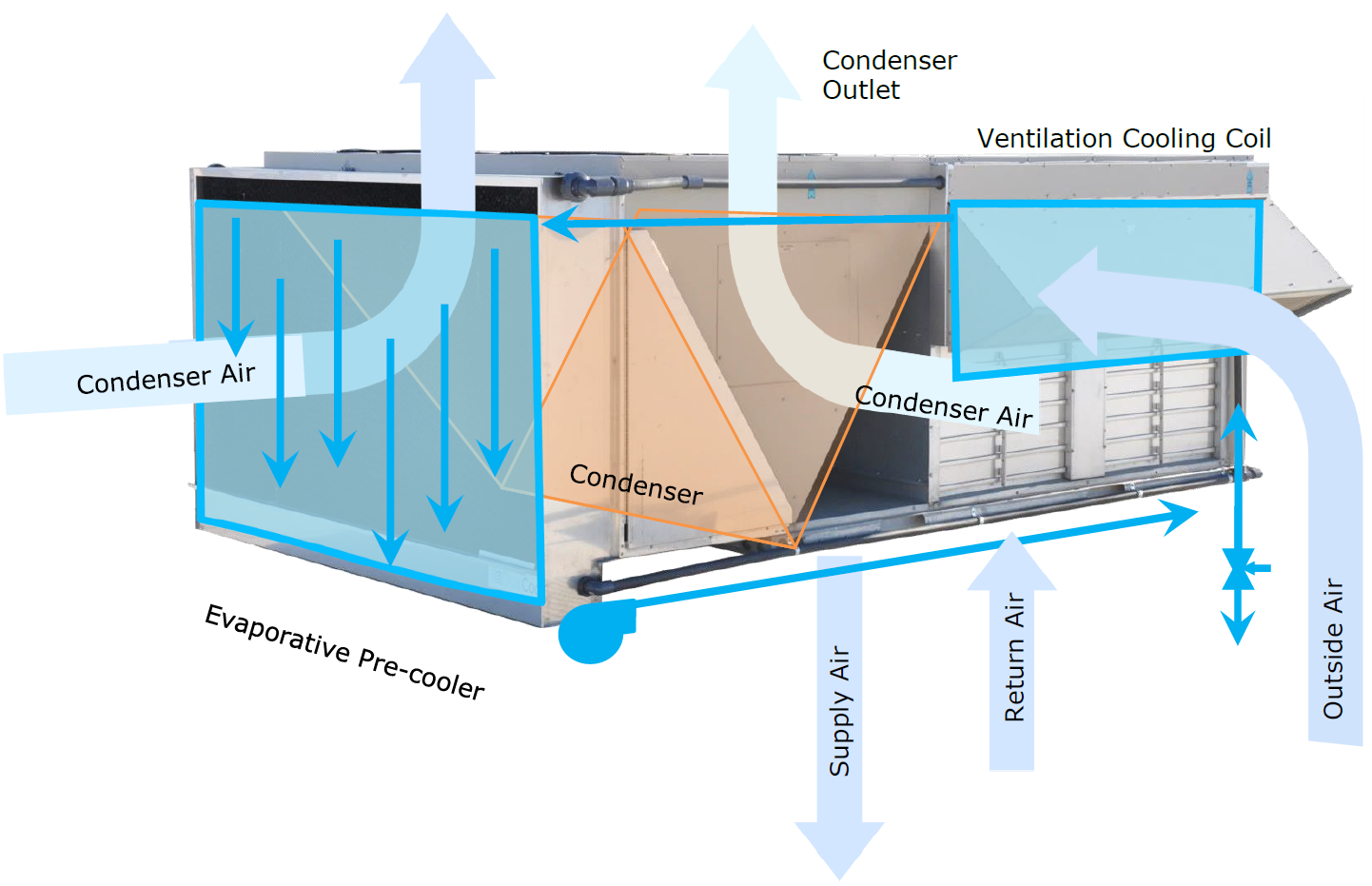

Evaporative cooling building technologies take advantage of the latent heat of vaporization for water to provide comfort cooling. Indirect evaporative cooling technologies achieve this without adding water vapor to the zone supply air. The technology studied here provides condenser coil air evaporative precooling and provides ventilation air precooling via a fully sealed water coil that does not add moisture to the supply air. According to a Public Interest Energy Research (PIER) study (Bourne, 2013), such technologies can improve equipment efficiency by 10 – 40% for an outside air wet bulb depression[1] of 10 – 20°F.

The California market for this technology is substantial because of the abundant regions with hot and dry summers and the abundance of buildings with suitable packaged rooftop units (RTUs). Market size is tempered by the facts that small RTUs and oversized RTUs with short compressor runtimes may not allow economically attractive installations. SDG&E gives a rebate of $65 per ton of RTU capacity.

The main objective of this study was to measure and verify energy, demand, and cost savings of the technology as installed on four RTUs at one commercial warehouse/office building in San Diego in Climate Zone 7. Three of the RTUs were 5-ton heat pumps and the fourth was a 7.5-ton gas/electric RTU.

The technology as installed functioned properly although one important energy saving feature was not set up (fan speed reduction), installation and commissioning was time consuming, and one additional opportunity for savings was identified. The technology reduced energy use and demand at high outside air dry bulb temperature. However, energy use was not reduced during low outside air temperature, and increased in sum. The poor energy performance is likely due to the supply fan speed reduction feature not being enabled due to an implementation oversight and the pump having unsophisticated control. Demand reduction compensated for the energy increase but the payback period was still significantly harmed.

The presence of the evaporative media in the condenser fan airstream and the water coil in the ventilation airstream add external pressure to the condenser and evaporator fans and thus were expected to increase energy usage. However, the researchers tested this impact of the evaporative media and did not find a perceptible energy increase as described in section Verification of System Operation and Design. The researchers did not test the pressure drop impact of the water coil in the ventilation airstream due to the difficulty and expected removal/re-installation cost.

The building owner’s main goal for the technology is to save money. They were happy with the comfort provided by the RTUs. However, they were reluctant to sign a maintenance contract and only signed a one yearlong contract upon commencement of this project. They were concerned that the technology may damage or reduce the lifetime of their RTUs. With the contract in place, the vendor assured the owner that the RTUs and their system warranty are in effect and that no damage should occur.

While all four RTUs were analyzed as shown in section Energy, Demand & Cost Savings, HP-3 data had the least anomalies and highest R². The simple payback period calculation for HP-3 yields 9.3 years for a parts-only scenario at list prices, and 40.8 years including all secondary costs and savings as tested, i.e. delivery, retrofit installation, maintenance agreement, SDG&E rebate and a discount provided by the vendor. Both scenarios are shown, because the secondary costs are highly variable from site to site.

When installed in suitable locations with a dry climate, and when commissioned and maintained properly, the technology can yield significant energy usage cost savings and demand cost savings even after accounting for water usage cost and pump energy usage cost. Otherwise, savings can be overshadowed by maintenance, pump energy and water cost.

The technology could be improved by better pump control, where the water pump should only run when it results in energy savings, which was not the case as tested. Future study could evaluate an improved iteration of the technology, and with the supply fan speed properly commissioned.

[1] Wet bulb depression is the difference between the dry bulb and wet bulb temperatures of a fluid (outside air in this case). Evaporative cooling effectiveness increases with increased wet bulb depression.