Project Info

COMPLETE

Project Title

Project Title

Project Title

Project Title

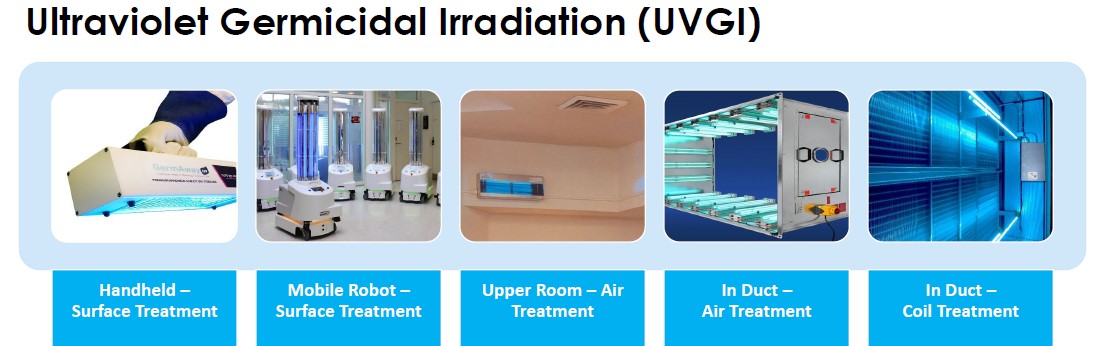

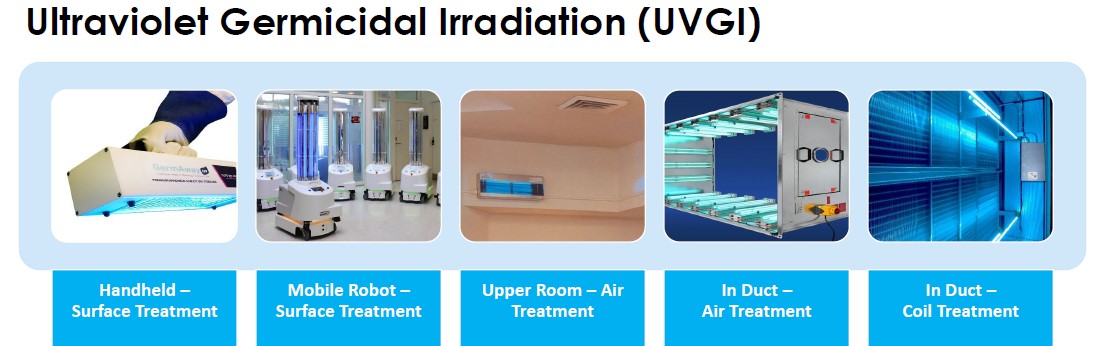

Electric Disinfection Technologies

Project Number ET21SCE0020 Organization SCE End-use HVAC Sector Commercial Project Year(s) 2021 - 2023Description

In response to COVID-19, commercial customers are seeking methods to safely return occupants to their buildings. This lab study will provide efficacy of several in-room light-based disinfection techniques.

Project Report Document

Loading PDF Preview...